February 7th, 2011 at 9:23 pm (Education, Mathematics, Reflection)

From the What I Learned Yesterday files…

I have always loved numbers, especially in terms of manipulating them. Remember those arithmetic drill books, endless columns of 3 + 6 and 12 – 5 and every other possible combination? I loved paging my way through them, filling up all of the blank spots. My grandmother’s living room had a big bay window with a flat base I could crawl onto (I don’t think it was intended as a seat), behind the curtains, and I loved to hole up there with that book. Even *better* was when I encountered those drills in elementary school, and they were *timed*! Hooray, a race!

But even before those memories glows a beautiful eureka moment I hope I’ll never forget. I was in daycare, somewhere between 4 and 5 years old, musing about multiplication (for no reason I can recall), when suddenly I Got It. I jumped up and ran around trying to share the shining vision that I’d had. The best I could do then was, “But it’s so simple! Two times two is just 2, two times!”

I still remember those words, and I remember the lack of a similarly excited response from the other kids. Was it incomprehension? Disinterest? I couldn’t seem to put my revelation into words that made sense to anyone else, and I was buzzing with commingled frustration and joy. At that moment, the “x” sign had ceased being an arbitrary symbol specifying a relation to be memorized. Instead, it had *meaning*. I was swimming in triumph at the feeling of having *cracked the code*, seeing yet another pattern but also the whys behind the pattern. (Of course, when I reached elementary school, I then got to memorize the multiplication tables, like everyone else. So much for eureka…)

I have a handful of other memories from that daycare. Conspiring with a friend to stash our pears from lunch, which we hated, in our pockets for later disposal. Sprawling on threadbare green carpet in front of the TV and goggling at afternoon cartoons. Singing “This Old Man, he played one, he played knick-knack on his thumb…” Discovering awe and predation on finding a black widow spider out back. Discovering how surprisingly hard other kids can pinch if you don’t wear green on St. Patrick’s Day. Shivering at horror stories about loose baby teeth being tied to a door and extracted with a slam, then rushing to the bathroom to inspect my own teeth for any worrisome looseness. But these have all faded in a way that my “2, two times” moment has not. And it left me with an appetite for that feeling of “Oh wow, I get it!” that is what makes the study of anything new so very delicious. More learndorphins, anyone?

2 Comments

0 of 2 people learned something from this entry.

February 4th, 2011 at 9:40 pm (Electronics)

Some time ago, I wrote about the demise of my touch-lamp. After the bulb burnt out, the lamp no longer responded to touch. A bit of research online suggested that the triac had likely been destroyed by the bulb’s dying throes. It looked like this could be solved by replacing that part, but I wasn’t quite up to tackling it on my own.

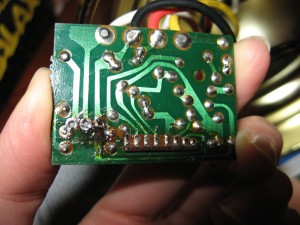

Times have changed! I read through some excellent repair instructions (thanks to a helpful commenter on my original post) which noted that most such lamps are equipped with a BT134 or BT136 triac, which can only handle up to 4 amps of current. Simply replacing this component with a BT139 triac should solve the problem forever — BT139s can handle up to 16 amps. Thus encouraged, I pulled the base off my lamp and found, to my delight, that the author of those instructions was spot-on: my lamp had a BT134! Here’s the whole circuit board, with the three-pronged triac on the right:

The letters on the triac say “PH 500E BT134 m9650”. I’ve located the equivalent BT139 part which costs all of $1.19. (What’s sad is that the BT134 costs $0.87, so for just 32 cents more, the manufacturer could have saved me this hassle. But most manufacturers probably don’t want to spend 32 cents more to build the lamp even if I am willing to pay 32 cents (or even a dollar!) for a higher-reliability product, since they’re doing mass production and mass advertising and trying to beat their competitors’ prices, etc.)

The next step is to remove the old part and replace it with the new one. My boyfriend Evan seized on this opportunity to teach me how to solder. He demonstrated soldering two wires together, and I eagerly observed and then got to try it myself. Unlike stained-glass soldering (my only previous such experience), you don’t use flux to prep the surfaces you’re joining, but instead the solder has a “rosin” core that performs the same function. The solder container had a warning on it that included “do not breathe the solder fumes, and wash hands before eating or smoking”, which cracked me up. You heat the soldering iron above 370 F (the melting point of solder), wipe the tip of the iron on a sponge to clean it, then “tin” the tip with a dab of solder. You use the iron to heat the wires to be soldered, so that they are hot enough to melt the solder as well (rather than touching the iron to the solder directly, which would be harder to direct where you want it). On touching the tip of the (solid) solder to the hot wires, it melts and flows into crevices and gaps to seal the wires together.

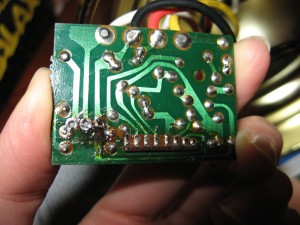

After joining the two wires, Evan showed me how to desolder, both with a copper wick (an absorbent braided fabric that sucks up liquid solder) and with an aspirator (that suctions the liquid solder away). Encouraged by this example, I desoldered the bad triac out of the circuit board. Here’s the result (this is the back side of the board shown above; the desoldering took place on the left side near the scorch mark):

Now I just need to wait for the new triac to arrive, then borrow a soldering iron and stick it back in. (Or maybe I’ll have my own soldering iron by then!) And then, victory over the broken lamp will be mine!

Update (Feb. 13, 2011): I have successfully fixed the lamp!

10 Comments

5 of 8 people learned something from this entry.

January 29th, 2011 at 4:34 pm (Chemistry, History)

It happened so long ago that it’s not really known how glass was first discovered. Certainly, lightning can strike a sandy beach and fuse silicon into glass bits (called fulgurites). The lightning has to reach 3270 F for this to happen, which would be difficult for ancient human cultures to reproduce, although there are tales of sailors inadvertently using sodium carbonate blocks around a fire ring on the beach, which reduces the melting point of glass to 2552 F, more likely to be within reach. According to wikipedia, a candle flame reaches about 1800 F, and a blowtorch gets up to 2370 F, and a Bunsen burner can get up to 2900 F — so chemistry lab students out there should be able to get right to work on glass-making!

It happened so long ago that it’s not really known how glass was first discovered. Certainly, lightning can strike a sandy beach and fuse silicon into glass bits (called fulgurites). The lightning has to reach 3270 F for this to happen, which would be difficult for ancient human cultures to reproduce, although there are tales of sailors inadvertently using sodium carbonate blocks around a fire ring on the beach, which reduces the melting point of glass to 2552 F, more likely to be within reach. According to wikipedia, a candle flame reaches about 1800 F, and a blowtorch gets up to 2370 F, and a Bunsen burner can get up to 2900 F — so chemistry lab students out there should be able to get right to work on glass-making!

Interestingly, glass made with sodium carbonate (also called niter) isn’t very stable; it gradually dissolves from contact with water (which makes terrible windows or water glasses). More stable glass can be made by adding calcium carbonate (lime), which is what is still done today. Other additives create color tints and other properties. Here are some glass recipes with suggested proportions. The wikipedia article on glass is full of other fascinating tidbits.

Interestingly, glass made with sodium carbonate (also called niter) isn’t very stable; it gradually dissolves from contact with water (which makes terrible windows or water glasses). More stable glass can be made by adding calcium carbonate (lime), which is what is still done today. Other additives create color tints and other properties. Here are some glass recipes with suggested proportions. The wikipedia article on glass is full of other fascinating tidbits.

And yes, glass is generally considered to be a solid (albeit an amorphous one, meaning it has no crystalline structure) rather than a liquid.

1 Comments

0 of 1 people learned something from this entry.

January 24th, 2011 at 11:00 pm (Engineering, Food, Plants, Productivity)

I recently had the pleasure of seeing tea being made into tea bags, right before my eyes! While in Boulder, CO, for a conference, I stopped by the Celestial Seasonings tea factory. They have not only a wonderful gift shop but also a free tea-tasting bar filled with great art and a free tour of their factory facilities.

After donning a hair net (plus beard net for whiskered men), we entered the factory and got to see black tea being milled (chopped up), filling the air with the most delicious odors. We walked past bales of herbs piled to the ceiling, filled with hibiscus and chamomile and tilia and all sorts of other things. We entered the tea room, where actual tea (black, green, and white) is stored, and then the “world famous” mint room, which of course is filled with mint. It turns out that a room full of mint bales, kept closed 99% of the time, builds up an overpowering mintness. Two feet into the room, my nose started to tingle and then burn faintly. I couldn’t get back out because of the flow of people coming in, so I edged over to the spearmint side of the room since it was less painful than the peppermint side.

Next we entered the main assembly room floor. This was so awesome I’m having trouble putting it in words. It was heaven for any tea-loving geek — like Willy Wonka’s Chocolate Factory, but with tea! Little conveyor belts sent half-assembled boxes of tea zooming around the room, pausing to be folded or stamped or sealed or wrapped in plastic, all by amazing automated machines. I wanted to stop and stare and figure out all of their gears and mechanics, but the tour kept pushing onward. Perhaps most intriguing was their “Robotic Palletizer”, which picked up packed cartons tea boxes in groups of six and stacked them precisely on a pallet. Later I saw the whole pallet being spun so it could be wrapped in plastic, a 6-foot stack of tea cartons all wound up like a cocoon. I could have spent the whole afternoon watching this busy, enchanting process.

Next we entered the main assembly room floor. This was so awesome I’m having trouble putting it in words. It was heaven for any tea-loving geek — like Willy Wonka’s Chocolate Factory, but with tea! Little conveyor belts sent half-assembled boxes of tea zooming around the room, pausing to be folded or stamped or sealed or wrapped in plastic, all by amazing automated machines. I wanted to stop and stare and figure out all of their gears and mechanics, but the tour kept pushing onward. Perhaps most intriguing was their “Robotic Palletizer”, which picked up packed cartons tea boxes in groups of six and stacked them precisely on a pallet. Later I saw the whole pallet being spun so it could be wrapped in plastic, a 6-foot stack of tea cartons all wound up like a cocoon. I could have spent the whole afternoon watching this busy, enchanting process.

Right there at the factory, the various herbs and constituents are magically converted into a lovely beverage experience. They mill, mix, and bag the tea (using unique no-string teabags so as to save frightening amounts of paper), then deposit the bags into boxes that are sealed and sent off for distribution and sale. You can get some glimpses of this geeky awesomeness through the Celestial Seasonings virtual tour; click on the tea cups marked “3” and “4”. Enjoy!

2 Comments

2 of 2 people learned something from this entry.

January 17th, 2011 at 8:56 am (Art, Engineering, History)

High-speed photography can capture athletes in action. But you need really high-speed photography to capture events like a nuclear explosion.

At the recent National Radio Science Meeting, I first encountered the idea of a rapatronic camera. These cameras have exposure times as short as 10 ns. They were developed in 1940 to capture the rapid expansion of a nuclear explosion, and they were gems of ingenuity. No mechanical shutter at that time could possibly open and close that quickly, so Harold Edgerton came up with a non-mechanical way of controlling the shutter: he put a Kerr cell between two polarizing filters oriented at 90 degrees from each other. Normally, no light would penetrate between the crossed polars. But when voltage is applied to the Kerr cell, it rotates the polarization of the incoming light 90 degrees—permitting it to pass through the second filter. By only activating the Kerr cell for a very short time, you obtain an ultra high-speed shutter.

You can view Edgerton’s hand-drawn circuit diagram to see how it worked.

Likewise, there was no way to mechanically advance the film fast enough to permit a single camera to take a sequence of high-speed shots, so in these tests they’d set up an array of the cameras, each with a slightly different delay. (Although I immediately wonder if you couldn’t have an electronically controlled refractive material behind the single lens to direct the light across a series of film segments so you wouldn’t have to physically move anything.)

The results are stunning:

At left is an explosion from Operation Tumbler-Snapper (1952), about 1 ms after detonation. The spikes along the bottom edge are evidence of the tower’s guy wires being vaporized by associated gamma rays. At right is an explosion from Operation Hardtack II (1958). This one was suspended from a balloon and the spikes here are the balloon’s mooring cables being vaporized. A beautiful ghostly array of such images is available from a

google image search on “rapatronic”.

One thing I haven’t been able to determine is the etymology of “rapatronic”. It may be that Edgerton just coined it (with “rapa” for “rapid” and “tronic” for “electronic”—but that’s just a guess). Please share if anyone knows more!

You can read more about Edgerton and his various innovations aside from the rapatronic camera. Brilliant guy!

4 Comments

4 of 4 people learned something from this entry.

Next we entered the main assembly room floor. This was so awesome I’m having trouble putting it in words. It was heaven for any tea-loving geek — like Willy Wonka’s Chocolate Factory, but with tea! Little conveyor belts sent half-assembled boxes of tea zooming around the room, pausing to be folded or stamped or sealed or wrapped in plastic, all by amazing automated machines. I wanted to stop and stare and figure out all of their gears and mechanics, but the tour kept pushing onward. Perhaps most intriguing was their “Robotic Palletizer”, which picked up packed cartons tea boxes in groups of six and stacked them precisely on a pallet. Later I saw the whole pallet being spun so it could be wrapped in plastic, a 6-foot stack of tea cartons all wound up like a cocoon. I could have spent the whole afternoon watching this busy, enchanting process.

Next we entered the main assembly room floor. This was so awesome I’m having trouble putting it in words. It was heaven for any tea-loving geek — like Willy Wonka’s Chocolate Factory, but with tea! Little conveyor belts sent half-assembled boxes of tea zooming around the room, pausing to be folded or stamped or sealed or wrapped in plastic, all by amazing automated machines. I wanted to stop and stare and figure out all of their gears and mechanics, but the tour kept pushing onward. Perhaps most intriguing was their “Robotic Palletizer”, which picked up packed cartons tea boxes in groups of six and stacked them precisely on a pallet. Later I saw the whole pallet being spun so it could be wrapped in plastic, a 6-foot stack of tea cartons all wound up like a cocoon. I could have spent the whole afternoon watching this busy, enchanting process.